Tech Start-up Minocular

Raipur startup Minocular is an integrated platform that hopes to simplify the process for the mining industry by leveraging technologies like IoT and drones.

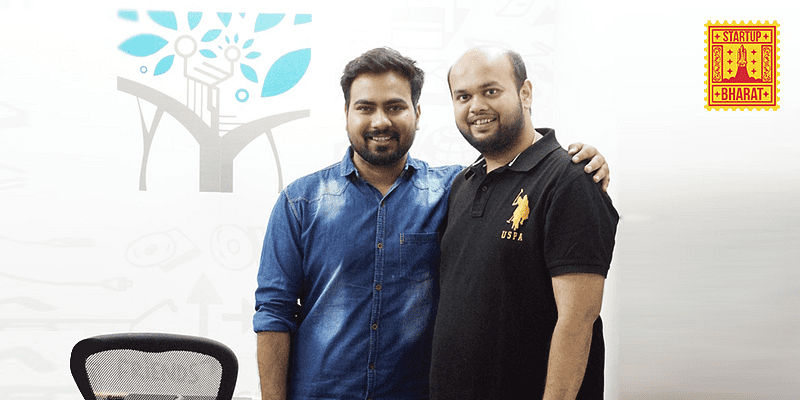

One of the main roadblocks in the mining sector is the lack of assessment of natural resources. Many areas remain unexplored, and the mineral resources in these areas are yet to be assessed. To drive transformation in the sector through technology, two friends – Puru Agrawal and Mohit Sahu founded Minocular in Raipur, Chhattisgarh, in 2018.

Miners know that the mines have mineral and resources, but how to scour them and where and when to dig was something they had no solution for,” says Puru. Both Puru and Mohit are from Chhattisgarh, and did their entire schooling and college at Raipur. Not only are the co-founders familiar with the town, but they feel that being based in a non-metro city like Raipur saved them a huge cost, which is essential for early-stage startups like Minocular. “The local talent available is evolving, which helps us to hire locally and keep everything in check,” says Puru.

“Chhattisgarh, Odisha, Jharkhand, Madhya Pradesh, and Maharashtra are majorly mining-dependent states, and being in Raipur provides us with an advantage of being close to these mines, and also gives us an advantage over other foreign players,” says Puru.

We visited a mine where we were called for a discussion on how technology can help them solve a problem related to the survey. But we noticed there was no use of technology at any stage of the mining process. One-and-a-half-years later, and after many visits to mines to understand their problems, working with the mine managers, surveyors, the blast managers, and dumper operators, Minocular was born,” Puru recalls.

Minocular essentially provides customised hardware to mining companies to collect data from ground resources. It also offers an integrated software platform that brings everything together, and then makes use of artificial intelligence and machine learning to give these companies short-term and long-term plans for the most optimised mining of resources. Explaining the end-to-end cycle of how Minocular works, Puru tells that a usual, medium-sized mine is spread across 10 KM area, which makes it almost impossible to monitor it through conventional methods. So, we first generate a 2D and 3D map of the entire area by drone mapping (Geo-Spatial Survey). “This helps the mine manager to view the entire mine in one screen, which was previously not done in mines,” he says. “Once we have the drone map, we gather quality data from the mines and different geological software, and impose it on the drone map. Our algorithm also calculates the approximate volume of mineral in the mines. So, the mines manager knows what quantity and what quality of mineral he has at what location,” explains Puru. Using an IoT sensor network, Minocular then connects all the people involved in the process – dumpers, excavators, weight bridge, and quality analysers to its platform. “All these are now integrated, and their functions are visible on the centralised dashboard,” adds Puru.

With all these data and algorithms, Minocular helps the mining team take informed decisions on ‘where to dig, how much to dig, and when to dig’ along with real-time monitoring, reporting, and alerts sent to all the users.